Step-by-Step Guide to Customizing Metal Name Plates

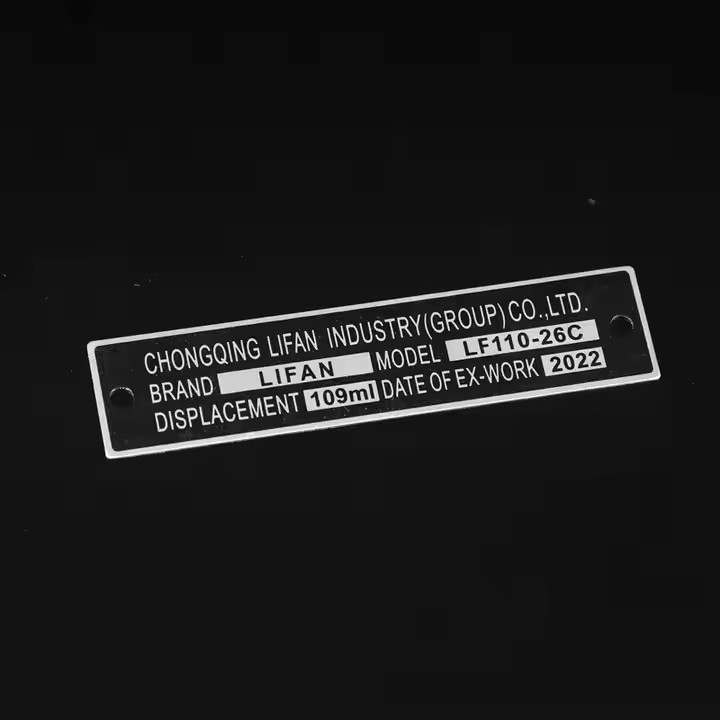

What Is an Industrial Name Plate? How Does It Differ from a Standard One?

11/09/2025

How to Design a Custom Metal Name Plate Based on Your Product

25/09/2025Step-by-Step Guide to Customizing Metal Name Plates

Step-by-Step Guide to Customizing Metal Name Plates

Custom metal name plates offer a durable and professional solution for product identification, branding, and regulatory compliance. Whether you’re marking industrial equipment, consumer products, or machinery, a well-designed metal name plate enhances your brand’s visibility and meets operational needs.

This guide will walk you through each step of the metal name plate customization process, from initial planning to final installation.

Step 1: Define Your Requirements

Before starting the design process, clarify your needs by answering these questions:

-

What information should the name plate display? (e.g., logo, serial number, instructions)

-

What environment will it be used in? (Indoor, outdoor, chemical exposure, heat)

-

What size and shape are required?

-

How will it be mounted? (Adhesive, screws, rivets)

-

What quantity do you need?

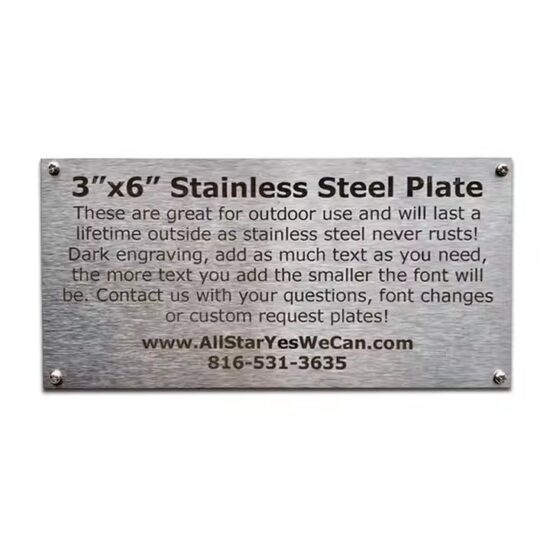

Step 2: Choose the Right Material

The choice of metal affects durability, appearance, and cost. Common materials include:

-

Aluminum: Lightweight, corrosion-resistant, cost-effective

-

Stainless Steel: Highly durable, chemical and heat resistant

-

Brass: Decorative and corrosion-resistant

-

Copper: Conductive and aesthetically pleasing

Step 3: Design Your Name Plate

Design elements include:

-

Layout of text and logos

-

Fonts and sizes for readability

-

Use of colors and finishes

-

Consideration for engraving or printing methods

Work with a graphic designer or manufacturer to create a clear, visually balanced design.

Step 4: Select Marking Technique

Choose the best method to apply your design:

-

Laser Engraving: Precise, permanent, ideal for serial numbers and text

-

Chemical Etching: Fine detail and contrast

-

Embossing/Debossing: Adds tactile dimension

-

Screen or Digital Printing: Full-color designs with protective coatings

Step 5: Decide on Surface Finish

Surface finishes improve appearance and protection:

-

Brushed or matte finishes for industrial look

-

Mirror polish for high-end products

-

Anodizing for aluminum to add color and durability

-

Clear coatings or powder coatings for extra protection

Step 6: Choose Mounting Method

Common mounting options include:

-

Adhesive backing for smooth surfaces

-

Rivets or screws for rugged or heavy-duty applications

-

Magnetic backing for removable plates

-

Snap-in or clip frames for easy replacement

Step 7: Prototype and Approval

Request a prototype or sample plate to verify:

-

Accuracy of design and markings

-

Material quality and finish

-

Proper fit for mounting

Make adjustments as needed before full production.

Step 8: Production and Quality Control

After approval, the manufacturer produces your plates in bulk. Ensure quality control processes are in place to verify:

-

Consistent marking clarity

-

Correct dimensions and finishes

-

Durable adhesion or mounting features

Step 9: Installation

Install the plates following best practices:

-

Clean surface before applying adhesive

-

Use correct fasteners where required

-

Confirm plates are securely attached and clearly visible

🏁 Conclusion

Customizing metal name plates requires careful planning and collaboration with your manufacturer to ensure the final product meets your functional and aesthetic goals. By following these steps—from defining requirements to installation—you can create durable, professional metal name plates tailored to your specific application.

💡 Pro Tip: Work closely with experienced suppliers who offer design support and quality assurance to achieve the best results.