Common Manufacturing Techniques for Metal Name Plates

How to Design a Custom Metal Name Plate Based on Your Product

25/09/2025

Why Choose Metal Name Plates as the Preferred Industrial Labeling Solution?

09/10/2025Common Manufacturing Techniques for Metal Name Plates

Common Manufacturing Techniques for Metal Name Plates

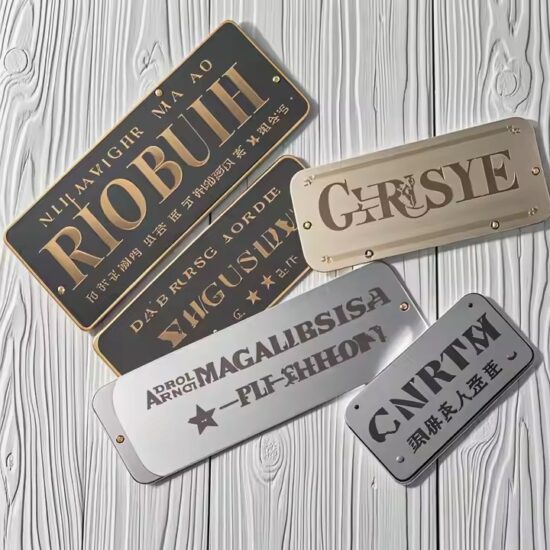

Metal name plates are used across industries for identification, branding, compliance, and safety purposes. The manufacturing technique used to produce these plates affects their durability, appearance, and cost.

In this article, we’ll explore the most common manufacturing techniques for metal name plates, their benefits, and suitable applications.

1. Laser Engraving

Overview:

Laser engraving uses a high-powered laser to etch designs or text directly onto the metal surface. This method produces clean, precise, and permanent marks.

Advantages:

-

Highly durable

-

Extremely precise

-

Ideal for serial numbers, barcodes, and fine details

-

Works well on aluminum, stainless steel, and anodized surfaces

Best For:

Industrial equipment, asset tracking tags, data plates

2. Chemical Etching

Overview:

Chemical etching involves applying a resist material to the metal, then using acid or chemicals to etch away the exposed areas. The result is a recessed design or text.

Advantages:

-

Great for high-detail designs

-

Consistent depth and line definition

-

Can be color-filled for contrast

-

Good for medium-volume production

Best For:

Logos, product labels, compliance plates

3. Embossing and Debossing

Overview:

Embossing raises parts of the metal surface, while debossing presses them down. This creates a three-dimensional effect.

Advantages:

-

Tactile and premium appearance

-

No ink or paint needed

-

Durable and weather-resistant

Best For:

Brand nameplates, luxury packaging, decorative labels

4. Screen Printing

Overview:

In screen printing, ink is applied to the metal surface through a mesh stencil. It allows for full-color designs and text.

Advantages:

-

Cost-effective for large quantities

-

Custom colors available

-

Good for flat and smooth surfaces

-

Requires protective coating for durability

Best For:

Brand labels, logo plates, indoor equipment

5. Digital UV Printing

Overview:

Digital UV printing uses ultraviolet-curable ink to print full-color graphics directly onto metal surfaces. The ink is instantly cured with UV light.

Advantages:

-

High-resolution images and gradients

-

Ideal for low-volume or custom orders

-

Fast turnaround

Best For:

Color-rich product branding, prototypes, promotional items

6. Stamping and Die Cutting

Overview:

Stamping uses high-pressure dies to cut, shape, or mark metal plates. Die cutting ensures uniform shapes for high-volume production.

Advantages:

-

Very fast and consistent

-

Excellent for creating shaped name plates

-

Can be combined with embossing

Best For:

Automotive labels, mass-produced ID plates, serialized tags

7. Anodizing (Aluminum Only)

Overview:

Anodizing is an electrochemical process that increases corrosion resistance and allows for colored finishes on aluminum. It can be combined with laser engraving or printing.

Advantages:

-

Adds color and durability

-

UV and corrosion resistant

-

Ideal for outdoor or industrial use

Best For:

Outdoor equipment tags, marine labels, control panels

🧰 Bonus: Combining Techniques for Enhanced Effect

Many metal name plates use a combination of techniques to achieve the perfect balance of appearance, durability, and functionality. For example:

-

Laser engraved + anodized aluminum for color + precision

-

Etched + color-filled + embossed for layered branding

-

Printed + clear coated for indoor use with aesthetic appeal

🏁 Conclusion

The right manufacturing technique for your metal name plate depends on its purpose, the operating environment, your branding needs, and your budget. From laser engraving to UV printing, each method offers distinct advantages. Working with an experienced manufacturer can help you select the most effective process for your product.

💡 Pro Tip: Always consider your plate’s lifecycle, exposure conditions, and design complexity when choosing a technique.