Identification Solutions of Metal Labels for Machinery

Strategies to Boost Customer Loyalty with Custom Metal Labels

07/08/2025

Design and Application of Metal Labels in Home Appliances

21/08/2025Identification Solutions of Metal Labels for Machinery

Identification Solutions of Metal Labels for Machinery

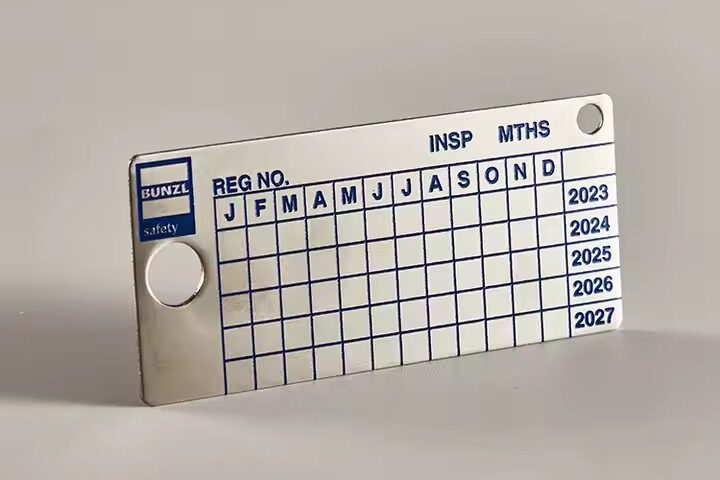

In the industrial world, proper identification of machinery is critical for safety, compliance, and operational efficiency. Metal labels offer a durable and long-lasting solution for tagging machines with vital information such as serial numbers, technical specifications, safety instructions, and maintenance records.

In this article, we explore the key types, benefits, and applications of metal labels used for machinery identification.

1. Why Metal Labels Are Ideal for Machinery

Unlike paper or plastic labels, metal labels are specifically engineered to withstand:

-

High temperatures

-

Abrasion and wear

-

Chemical exposure

-

UV radiation and weather

-

Vibration and heavy-duty use

These features make them ideal for use in harsh industrial environments such as manufacturing plants, construction equipment, automotive systems, and heavy machinery.

2. Common Materials for Machinery Metal Labels

Different metals offer different performance characteristics:

| Material | Durability | Corrosion Resistance | Common Use |

|---|---|---|---|

| Stainless Steel | ★★★★★ | ★★★★★ | High-heat, corrosive environments |

| Anodized Aluminum | ★★★★☆ | ★★★★☆ | Lightweight machinery, indoor/outdoor use |

| Brass | ★★★★☆ | ★★★★☆ | Decorative or classic-looking plates |

| Zinc Alloy | ★★★☆☆ | ★★★☆☆ | Die-cast applications with texture needs |

🟢 Tip: Stainless steel is preferred for high-performance machinery due to its superior heat and corrosion resistance.

3. Types of Information Displayed

Metal machinery labels are used to communicate:

-

Manufacturer name and logo

-

Serial number or machine ID

-

Compliance certifications (e.g., CE, UL)

-

Operating instructions or warnings

-

Technical specifications (voltage, weight, pressure)

🟢 Example: A CNC machine may display model number, power rating, and maintenance intervals—all engraved on a stainless steel plate.

4. Popular Marking Methods for Metal Labels

The way a metal label is marked greatly affects its readability and lifespan. Here are the most common methods:

✅ Laser Engraving

-

Permanent, precise, and high-resolution

-

Ideal for serial numbers, QR codes, and safety data

✅ Etching and Filling

-

Acid or chemical etching with color-fill

-

Adds contrast and a premium look

✅ Embossing/Debossing

-

Raised or recessed lettering for tactile and durable finish

-

No ink needed; extremely long-lasting

✅ Screen Printing (with protective coating)

-

Good for colorful graphics, but requires a protective layer to prevent fading

5. Attachment Methods

Metal labels for machinery must remain fixed under vibration and wear. Common mounting solutions include:

-

Riveting or bolting (permanent, secure)

-

Industrial adhesives (for flat and smooth surfaces)

-

Welding (for very high-security tags)

-

Magnetic backing (temporary or portable machinery)

🟢 Note: For heavy-duty equipment, mechanical fastening is often the most reliable choice.

6. Industry Applications

Metal machinery labels are widely used in:

-

Manufacturing – CNC machines, conveyor systems, injection molders

-

Construction – Excavators, cranes, concrete mixers

-

Automotive – Engine tags, VIN plates, transmission labels

-

Energy Sector – Generators, transformers, compressors

-

Aerospace – Aircraft components, test rigs, ground support tools

7. Compliance and Safety Benefits

Using permanent metal identification labels helps companies:

-

Comply with industry standards (ISO, ANSI, OSHA)

-

Pass equipment audits and inspections

-

Prevent misuse or misidentification of machinery

-

Improve traceability in case of failure or recall

🟢 Bonus: QR codes or NFC chips can be embedded for digital tracking and maintenance history.

🏁 Conclusion

Metal labels play a crucial role in the safe and efficient operation of machinery. Their durability, clarity, and ability to resist environmental challenges make them the go-to solution for industrial identification.

Whether you need serial number plates, rating labels, or warning plaques, choosing the right metal label ensures your machinery remains compliant, traceable, and easy to service.

💡 Tip: Partner with a custom metal label manufacturer to tailor solutions for your equipment, environment, and compliance needs.