Key Considerations When Customizing Aluminum Wine Labels

Why Premium Wineries Are Switching to Aluminum Wine Labels

13/07/2025

Are Aluminum Wine Labels Waterproof and Scratch-Resistant?

13/07/2025Key Considerations When Customizing Aluminum Wine Labels

Key Details to Consider When Customizing Aluminum Wine Labels

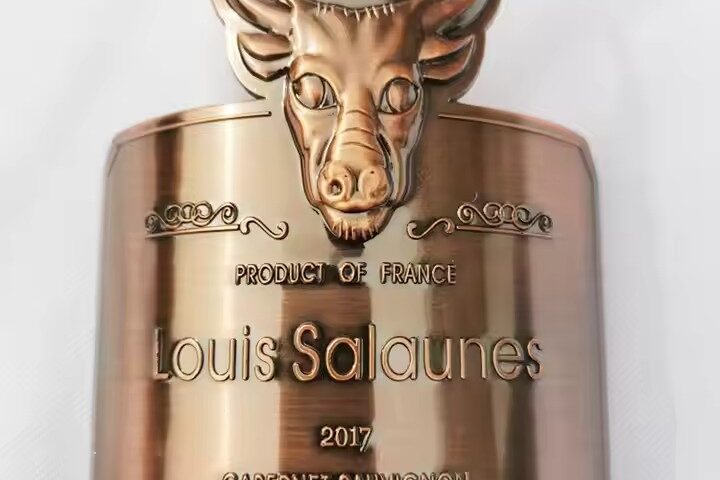

Customizing aluminum wine labels offers a powerful way to elevate your product, build a premium brand image, and stand out in a competitive market. However, the success of a custom aluminum label depends on more than just choosing a beautiful design — it requires attention to detail across several key areas.

Whether you’re a winery, distributor, or private-label brand, here are the most important details to consider when creating custom aluminum wine labels.

1. Label Size and Bottle Fit

Your aluminum label should complement the shape and size of your bottle. Unlike paper, aluminum has limited stretch, so accurate measurements are critical. You’ll need to determine:

-

Exact height and width

-

Placement area (front, back, neck, capsule)

-

Whether the label is flat or needs to curve around the bottle

👉 A good fit enhances aesthetics and prevents peeling or poor adhesion.

2. Adhesive and Application Method

Because aluminum is rigid compared to paper, the choice of adhesive is crucial. Factors to consider include:

-

Surface material of the bottle (glass, frosted, coated)

-

Curved vs. flat surfaces

-

Manual vs. machine application

-

Storage conditions (humidity, cold chain, etc.)

A high-quality adhesive ensures long-term durability and prevents lifting or bubbling.

👉 Be sure to discuss application methods with your supplier early in the design phase.

3. Design and Finishing Techniques

Aluminum labels support a wide range of premium design options, such as:

-

Embossing / Debossing

-

Laser engraving

-

UV printing

-

Anodized or brushed finishes

-

Cut-outs or layered designs

When designing, consider both aesthetic appeal and brand messaging. A minimalist brushed aluminum look may work for modern brands, while ornate embossing might better suit heritage wine lines.

👉 Balance visual impact with legibility and practical usability.

4. Color and Surface Treatments

Aluminum doesn’t absorb ink like paper, so special surface treatments may be needed:

-

Clear coating or lacquer to allow printing

-

Anodized coloring for vibrant, long-lasting shades

-

Matte vs. gloss finishes to align with brand tone

Work closely with your supplier to ensure your color expectations match the real outcome on metal.

👉 Always request pre-production samples or color proofs.

5. Quantity and Budget Planning

Custom aluminum labels require more complex tooling and processes, which means:

-

Higher cost per unit (especially in small quantities)

-

Tooling/setup fees for embossing or die-cutting

-

Longer production lead times

To optimize cost, plan ahead and consider bulk ordering or consolidating multiple SKUs in a single run.

👉 Ask your supplier if they offer small-batch customization or trial runs for new designs.

6. Compliance and Information Requirements

Don’t forget the functional side of wine labels. Ensure there’s enough space for:

-

Legal information (alcohol content, origin, sulfites)

-

Barcodes or QR codes

-

Batch numbers or vintage dates

With aluminum, you can layer a printed label on the back or include laser-engraved codes for a clean, compliant finish.

👉 Form meets function—compliance doesn’t have to sacrifice style.

7. Sustainability and Material Sourcing

Aluminum is recyclable and supports eco-conscious branding, but make sure to:

-

Confirm the recycled content percentage

-

Avoid using PVC backings or adhesives with harmful chemicals

-

Highlight the sustainable aspects in your marketing if relevant

👉 Many premium wine buyers value eco-responsibility as part of the brand story.

🏁 Final Thoughts

Custom aluminum wine labels are a bold and elegant way to differentiate your product. But to achieve the best result, it’s important to focus on technical accuracy, visual design, material compatibility, and brand strategy.

Partner with an experienced label manufacturer who can guide you through design, prototyping, and production. The right label isn’t just decoration—it’s a powerful tool to enhance customer perception and build lasting brand value.