Laser Engraving and Screen Printing Technologies for Metal Wine Labels

Durability and Lifespan of Metal Wine Labels Explained

15/01/2026Laser Engraving and Screen Printing Technologies for Metal Wine Labels

Laser Engraving and Screen Printing Technologies for Metal Wine Labels

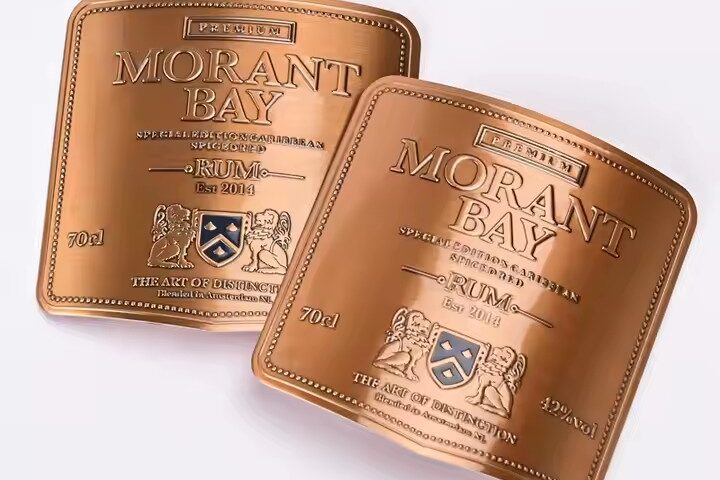

Metal wine labels are a sophisticated way to showcase a brand’s identity and add a premium touch to wine bottles. The choice of printing and marking technology greatly impacts the quality, durability, and aesthetics of these labels. Two of the most popular methods used in metal wine label production are laser engraving and screen printing.

In this article, we’ll explore these technologies, their advantages, and when to use each for your metal wine labels.

1. Laser Engraving Technology

Laser engraving uses focused laser beams to etch precise, permanent designs directly onto the metal surface. It removes a thin layer of the material, creating crisp and detailed markings without the need for inks or chemicals.

Advantages:

-

Durability: The engravings are permanent, resistant to fading, scratching, and wear.

-

Precision: Allows for intricate designs, fine text, and complex logos with high accuracy.

-

Clean Process: No ink or solvent usage, making it eco-friendly.

-

Versatility: Works well on various metals including aluminum, stainless steel, and brass.

Best Use Cases:

-

Luxury and limited edition wine labels

-

Detailed logos and serial numbers

-

Long-lasting branding where durability is critical

2. Screen Printing Technology

Screen printing involves applying ink through a fine mesh stencil onto the metal label surface. It allows for vibrant colors and the printing of multiple layers for rich designs.

Advantages:

-

Color Variety: Supports a broad spectrum of colors, including metallic and opaque inks.

-

Cost-Effective: Ideal for large production runs with consistent quality.

-

Custom Effects: Enables textures, gradients, and special finishes.

-

Fast Production: Efficient for bulk orders with simpler designs.

Best Use Cases:

-

Bold, colorful wine labels

-

Promotional and seasonal designs

-

Large-volume productions requiring consistent color application

3. Comparison Summary

| Feature | Laser Engraving | Screen Printing |

|---|---|---|

| Durability | Extremely high, permanent marks | Good, but ink can wear over time |

| Color Options | Limited to metal surface color | Wide range of vibrant colors |

| Detail Precision | Very high | Moderate |

| Environmental Impact | Eco-friendly, no inks or solvents | Uses inks and cleaning solvents |

| Ideal Applications | Premium, detailed designs | Colorful, high-volume labels |

📌 Conclusion

Choosing between laser engraving and screen printing depends on your brand’s needs and label design. Laser engraving excels in durability and intricate detail, making it perfect for premium wines. Screen printing offers vibrant color and cost efficiency for larger orders with bold designs.

Consult your metal wine label supplier to determine the best technology for your specific branding and production goals.